Design Approval & Support

Nobody knows the design of your product better than you do. Gordon & Gordon Engineering can advise you of those designs to ensure cost-effective solutions that maximize your margins while meeting your project requirements.

Some of our design services include:

- Review your designs (drawings, specifications, reports, models, etc.)

- Provide & compare engineering alternatives

- Provide proper substantiation with design standards/methods

- Validate analytical models & calculations

- Develop operating & maintenance procedures

- Consultant DER services for Parts 23, 25, 27, & 29 airplane and rotorcraft structures, all materials & processes, fire protection, and flammability (including test plan approval and test witnessing).

We provide all the technical support necessary for required design approvals, certification, and permitting of our clients' projects.

Design Capabilities

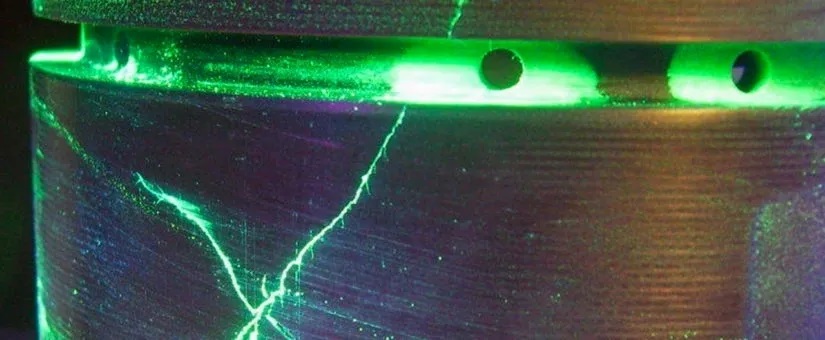

We provide proven and extensive knowledge and experience-base with all design and construction material types: metals, polymers, ceramics, composites, and concrete, including fabrication, processing, testing, and joining methodologies to assure proper material and process selection.

Design experience includes critical components, mechanisms, and systems, for vehicles (terrestrial, nautical, aircraft, spacecraft), tooling, structures, and manufacturing facilities.

We can produce procurement, material, process, inspection specifications, and operating and maintenance procedures to satisfy your industry requirements.

Additionally, we can produce CAD drawings using AutoCAD following ASME Y14.5 or your drawing standards.

We have an in-depth understanding of traditional and finite element modeling analysis of structures and mechanisms to assure that critical component have adequate margins to withstand static, dynamic, thermal, and other environmental load conditions throughout the product lifecycle.

Gordon & Gordon Engineering and its engineers are licensed in Alabama, Arizona, California, Florida, Louisiana, Missouri, South Carolina, Utah, and Washington State and are insured for professional liability.

Our design service work's performance would include the requisite engineering oversight and involvement to support our engineering approval of technically-acceptable reports and any relevant drawings as the Engineer of Record.

Should any engineering tasks require engineering approval in any of the other 50 US states, 4 US territories, or the District of Columbia, we will use our NCEES Records and flawless Model Law Engineer (MLE) designations to obtain rapid temporary or permanent engineering licensure in these other jurisdictions via professional engineer comity.

Design approval through traditional signature and impression stamp or electronic signing and sealing. Gordon & Gordon Engineering uses the DocuSign Signature Appliance for our electronic signature of your design package of engineering documents using a secure hash standard authentication code generator that assures document integrity, industry-wide credibility, and professionalism.

Materials and Process (M&P) Consulting

To guarantee consistency in your production, you need objective experts.

You need a partner whose skill is the material selection and identifying the kind of process conditions that cause chronic problems with quality, reliability, and cost.

We apply a time-tested strategy and a wealth of experience to your company's unique challenges by adapting proven material and process (M&P) methods to your existing capabilities and improvements that you are planning. The result is more value in your products and processes!

With decades of experience, Gordon & Gordon Engineering provides professional materials and processes fabrication, assembly, inspection, and repair expertise.

We even have the authority to approve M&P specifications for general aviation and transport category aircraft.

We're more than specs and surface preps!

M&P Capabilities

Metallic Materials

Nonmetallic Materials

CONSULTANT DER AIRPLANES AND ROTORCRAFT STRUCTURAL ENGINEERING

In addition to the design and materials & processing work, we are we are deeply familiar with Title 14 of the Code of Federal Regulations that comprise the Federal Aviation Regulations (FAR) and its predecessor, the Civil Air Regulations (CAR). Included in this familiarity are the associated FAA Orders, Policy Statements, Advisory Circulars, and other regulatory guidance.

Our knowledge base includes operations with FAA Aircraft Certification Branches (formerly ACOs), Certificate Management Sections (formerly MIDOs), and Flight Standards District Offices (FSDOs) with a deep understanding of FAA-delegated representation including Designated Engineering Representative (DERs), Designated Airworthiness Representatives (DARs), Designated Manufacturing Inspection Representatives (DMIRs), and Organization Designation Authorizations (ODAs).

As a Consultant DER, we provide a service to approve technical data to the FAA for our clients including engineering reports, drawings, M&P specifications, data for major repairs and major alterations, and other data pertinent to structural applications using FAA Form 8110-3.

Additionally, our experience base allows the non-DER consultations for our applicant clients’ showing of compliance, dispositioning of minor nonconformances via Material Review Board (MRB), Partnership for Safety Plans, Project Specific Certification Plans, and other documentation for Type Certificate (TC), amended TC, Supplemental Type Certificate (STC), amended STC, test and computation Parts Manufacturer Approval (PMA), and Technical Standard Order Authorizations (TSOA) with the FAA Structural Engineering DER approvals where appropriate.

Our principal engineer is a Consultant Designated Engineering Representative (DER) that is authorized to make findings to 14 CFR Parts 23, 25, 27, & 29 airworthiness regulations for normal and transport categories of all airplanes and rotorcraft.

Delegated functions and authorized areas are as follows: design & construction, static analysis, fire protection, and flammability (including test plan approval and flammability test witnessing with FAA Project Office Coordination) for wing, fuselage, empennage, landing gear, flight controls, doors, process specifications, material allowables & specifications, and interior materials (unlimited delegation for all materials: metallic and nonmetallic). Additional 14 CFR Part 23 & 25 delegations: design & construction for interior arrangements (unlimited delegation for all materials: metallic and nonmetallic) and special delegations for service documents, major repairs, and major alterations.